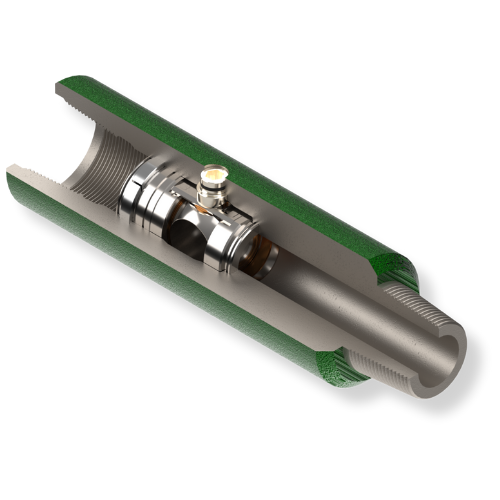

Inside Blow Out Preventer Valves

M&M Oil Tools IBOP Valves automatically shut off uncontrolled flow to protect the swivel, kelly hose, and surface equipment from high-pressure kicks. Available in compact one-piece and high-flow two-piece designs, our poppet-style valves open automatically for normal circulation and can be quickly stabbed in as a standby safety valve during kick situations.

.png?width=100&height=100&name=Blue%20Wave%20Cert%20(1).png)

.png?width=100&height=100&name=Blue%20Wave%20Cert%20(1).png)

Features & Benefits

Our IBOP valves use a durable poppet-style check mechanism with a metal-to-metal seat design to minimize erosion during high-rate circulation. Offered in multiple configurations with full material traceability, these valves deliver reliable well control performance, reduced operating torque, and compatibility with a wide range of drill string connections.

Automatic Well-Control Protection

Automatically stops uncontrolled backflow and protects kelly hose, swivel, and surface equipment from high-pressure kicks.

Poppet-Style Metal-to-Metal Seal

Conical poppet and metal-to-metal seat minimize erosion and deliver dependable sealing during long-term, high-rate circulation.

One- or Two-Piece Construction

Compact one-piece for tight spaces or critical weight limits; two-piece available for larger internal flow areas and enhanced circulation.

Fast Stab-In Emergency Use

Optional release assembly allows the IBOP to be stabbed quickly into drill pipe, tubing, or casing as a standby surface safety valve.

High-Strength Materials & Thread Options

Offered with multiple thread types—including left-hand connections—matched to maintain drill string tensile strength capacity.

Reduced Operating Torque

Patent-protected floating ball and spring-loaded seat design reduces torque by up to 50% compared to competitive valves.

API Q1 Quality & Full Traceability

Manufactured under M&M’s API Q-1 quality system with material certificates, test reports, and Certificates of Conformance provided with every valve.

Smooth OD for Versatile Placement

One-piece design features a smooth outside diameter, allowing installation anywhere in the drill string where space is limited.

What Our Customers Say

Cupping chicharrones hexagon vaporware. Helvetica beard taiyaki, DIY drinking vinegar PBR&B tonx vape godard tofu. Meggings echo park taxidermy big mood asymmetrical next level.

John Smith

Director of Marketing

Cupping chicharrones hexagon vaporware. Helvetica beard taiyaki, DIY drinking vinegar PBR&B tonx vape godard tofu. Meggings echo park taxidermy big mood asymmetrical next level.

John Smith

Director of Marketing

Cupping chicharrones hexagon vaporware. Helvetica beard taiyaki, DIY drinking vinegar PBR&B tonx vape godard tofu. Meggings echo park taxidermy big mood asymmetrical next level.

John Smith

Director of Marketing

Need the Right IBOP Valve for Your Operation?

Contact our team for sizing, thread options, or technical guidance. We’ll help you select the correct IBOP configuration for your drilling or workover program.