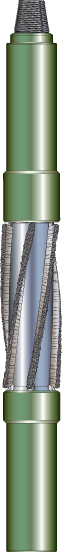

M&M Casing Brush Tool

Mechanical cleaning of the ID of the casing is critical for

successful completions in new wells and workovers. Debris in the

casing ID can prevent the proper setting of sealing elements & slips

used in downhole tools and small particulates can cause formation

damage. The M&M Oil Tools Casing Brush tool’s 360-degree contact

does not require rotation, works RIH & POH and can reach into

corrosion pits and coupling recesses that cannot be cleaned by

casing scrapers. Our brush tool has a proven, 15-year track record

of cleaning the casing ID to dislodge this hidden debris, thereby

reducing the potential for formation damage. The robust design of

M&M Oil Tools Casing Brush Tool with a large internal diameter and

precise brush placement can withstand the roughest high-speed

rotation and reciprocation in vertical, deviated or horizontal

wells.

Features & Benefits

Our mandrel is made from high strength, heat-treated alloy steel bar

stock with integral upper and lower tool joint connections. There

are no welds or castings which can compromise the tool strength of

the string or which must be inspected after every run.

Brushes are positively retained in the retainer pockets by solid

machined shoulders. There are no fasteners or other parts that can

loosen causing miss-runs or be lost causing fishing jobs.

Our brushes are made using a premium grade of stainless-steel wire

so they will not contaminate corrosion resistant alloy (CRA) tubular

goods.

Our brush bristle design provides superior scrubbing action while

eliminating the bending and breakage seen in other designs; so, it

is not necessary to run a magnet pickup tool to capture broken

wires.

Bevels on the upper and lower guide rings prevent the tool from

hanging on casing connections or when entering downhole

restrictions.

Large internal bore and external flow path allow high-rate

circulation for maximum wellbore cleaning.

Our M&M Oil Tools Casing Brush Tool are available in sizes for use

in 4 ½” to 20” OD casing.